YOUR EV Start-Up HAS ITS Hands Full

Any EV start-up faces a wide range of unique challenges. Between engineering and design, marketing, sales and distribution—not to mention the matter of actually producing the vehicles in question—launching a new vehicle brand is a massive undertaking.

In the midst of all that, it’s understandable that product information often gets treated like an unpleasant afterthought.

Unfortunately, and I’m just going to say this, deprioritizing product strategy is a terrible idea. Assembling your product information in a haphazard, “Let’s just get this done” fashion can negatively impact your customer experience, your overall costs, the profitability of your service operation and even operational efficiency of multiple areas within your company.

Building Information Strategy for A New EV Start-Up

Having worked with countless manufacturers on their information strategy, it’s wise to move carefully when laying your product strategy groundwork. It’s important to cover all your bases, and it’s important to tie everything together with intention and cohesion.

That’s because, built properly, good information strategy effects many bottom-line business concerns in beneficial ways, ways like:

Lower warranty costs

Lower warranty costs - Fewer product recalls

- Improved regulatory alignment and reduced legal liability

- Trouble-free product launches

- Repeat business (via customer satisfaction and customer loyalty)

- Faster repairs

- Greater service profitability

- Creating third-party income streams

By employing best practices when first establishing their product information strategy, companies can enjoy long-range operational efficiencies around the development, maintenance and distribution of product information.

Companies that employ best practices when BUILDING their product information strategy enjoy unique, long-range operational efficiencies.

Simplifying Product Information for Electric Vehicles

To help create some structure around the concern of product information and to hopefully make the whole undertaking a little less daunting, I’ve developed a Minimum Viable Product for Aftersales Checklist. It breaks all product information into two categories: Service Information and Owner Information, then further defines all the aspects of each.

Of course, every company is different, and every product is unique. But I’ve created this list to serve as a starting point for discussion and consultation.

By examining this list, companies might consider:

- Which internal areas generate which pockets of raw data and information

- What end users need to access the information deliverables

- How best to aggregate and prepare that information for optimal maintenance

- How best to distribute the relevant info to the appropriate users

After we’ve broken down the list, we’ll touch on some best practices for creating, storing and updating that information to create an information strategy with legs and efficiency, one that flows easily with engineering and design changes to create a smooth, trouble-free information flow from one model year to the next.

And so, without further ado, on to the checklist(s).

Minimum Viable Product (MVP) Checklist for EV START-UP Service Information

- Removal and Installation Procedures

- Diagnostic Procedures (traditional or guided)

- Flat Rate Studies

- Accessory Installation Sheets

- Wiring Diagrams

- Body Repair Information

- Electronic Parts Catalogue

Removal and Installation Procedures

Process instructions for the installation and removal of vehicle components. Prescribes approximate timing for each operation.

Inputs: Engineering drawings and CAD data (drawn from Engineering)

Relevance: Quite simply, offering removal and installation procedures encourages technicians to work on your product by resolving uncertainty or unfamiliarity with your product. Without this content, the end-user (consumer, fleet owner, etc.) can’t get anyone to service your products. The skeletal structure of an entire service operation rests on this material.

Flat Rate Studies

Time studies establish industry standards for reasonable time-to-complete specific service operations on a particular product. These standard times make it possible to charge fixed fees for each technical service operation.

Inputs: Prototype/validation vehicle for teardown, plus all information from Diagnostic Procedures, plus SBOM

Relevance: Flat rate offers a competitive advantage in that customers see fixed fee scales as being more fair than hourly. Flat rates allow service outlets to set clear expectations around their team’s efficiency. A proficient technician—one who can complete accurate repairs in a shorter amount of time—can earn more money in a flat-rate environment.

Accessory Installation Sheets

Similar to Removal and Installation Procedures, but specifically designed for non-essential aftermarket accessories.

Relevance: From performance parts to cosmetic modifications, after-market accessories constitute a lucrative method for increasing part sales. Accessories create an added layer of customer engagement and satisfaction. When accessories—and their installations—are OEM-official, they enjoy the additional distinction of branded quality.

Wiring Diagrams

Layouts and schematics for all wiring, component modules and connectors employed on a vehicle.

Inputs: CAD, Prototype vehicle, Pre-production vehicle, circuit diagrams, circuit list, signal/name/function list, PIA information, harness prints, connector views, pre-harness connectors, module topology and DTC list

Relevance: Wiring diagrams aid factory assembly, but they’re essential to any technician who needs to work on—or even work around—the installed electrical.

Body Repair Information

Necessary for the removal, installation and replacement of vehicle body components.

Relevance: Body repair is critical to the longevity of a vehicle. Certain types of body damage can impact mechanical operation and create major safety concerns. Body repair information enables OEM service outlets to perform body repairs—opening that income stream for the manufacturer—and can also be sold to third party service outlets.

Electronic Parts Catalog

Parts ordering traditionally involved static (printed or PDF) parts catalogs and lots of phone calls. Electronic parts catalogs (or EPCs) simplify that process—and eliminate the phone calling. The most advanced options offer multiple search options, and let technicians locate parts visually through exploded 2-D and 3-D assembly views. These cutting edge EPCs are linked to the original assembly Bill of Materials so that as parts, part names or suppliers change, the catalog itself automatically updates accordingly.

Relevance: EPCs remove friction from the parts ordering process. This helps the OEM sell more parts. Advanced EPCs also save money for dealerships and service outlets by reducing human error and eliminating incorrectly ordered parts.

Why Service Information Matters

I’ve been talking to repair techs and their service managers, and there’s a clear recurring theme: technicians prefer a job order they’ve seen before over anything new and unfamiliar.

I’ve been talking to repair techs and their service managers, and there’s a clear recurring theme: technicians prefer a job order they’ve seen before over anything new and unfamiliar.

Translation: if 4 vehicles turn up for repair—and one is a BEV—the techs will fight over the 3 Internal Combustion Engine repair orders and leave the BEV to sit.

Which means extended wait times for the BEV end user.

First-Time Fix Rate (FTFR) is the metric for measuring service operation success.

Poor FTFR rates can signal frustration—for both the technician and your customer.

Which means a whole slew of problems for the BEV manufacturer, starting with damaged customer loyalty. Imagine a customer saying, “They used to get my standard vehicle back to me in 3-5 business days. Since I bought this EV, it’s in the shop for weeks at a time. I’m never buying an EV again.”

Technicians Avoid BEV (But It Doesn’t Have to Be That Way)

This troubles the hell out of me, both as a consumer and as someone involved in service & repair for new technologies.

Based on my own experience in service—once upon a time, I was a technician myself—I believe it’s a matter of reducing friction for these technicians. I believe prescriptive guidance—helping technicians quickly find the most likely root cause and making it easy to validate that root cause—is the key to lessening the friction of BEV repair.

First-Time Fix Rate (FTFR) is the metric for measuring the success of your service operation. Low FTFR rates can signal frustration—for both the tech and your customer.

So, everything I do ties back to helping companies improve the speed & precision of their repairs. We’ve developed methods to give techs access to the latest VIN/PIN-specific info for the precise model they’re working on, aggregating all—and only—the relevant publications: technical service bulletins, wiring diagrams, parts catalogs. We even offer guided diagnostic tools to help them fix every product correctly the first time they see it.

We’ve developed methods to let techs access all—and only—the latest VIN/PIN-specific info for the precise model they’re working on.

But the first thing companies need to pay attention to is providing technicians with the information they need to complete the necessary repairs and get that product back to its fleet or its owner.

Minimum Viable Product (MVP) Checklist for Owner Information

- Operator’s Manual

- Essential Information Guide (printed)

- Quick reference Guide (printed)

- 1st Responder’s Guide

- Service and Warranty Manual

Operator’s Manual

A complete and detailed description of every aspect of vehicle operation. All critical warranty/regulatory/compliance/disclaimer information. Single source of truth for product.

Inputs: CAD, product feature list, prototype/pre-prod vehicle, engineering and legal approval

Relevance: Operator information is critical to product operation and operator experience. It plays a role in everything from safety to product feature awareness. Operator content is required by law as the definitive repository of all vehicle information. Complicating matters, different countries and regions hold their own unique requirements regarding where and how this information is to be made available and in what format.

Essential Information Guide (Printed)

A brief document, usually about 100 pages, covering all safety information and emergency procedures.

Inputs: CAD, product feature list, prototype/pre-prod vehicle, engineering and legal approval

Relevance: The Essential Information Guide (EIG) provides important coverage for manufacturing brands by communicating relevant safety disclaimers and other mandated information, e.g., what to do in an emergency, how to change a road wheel, etc.

Quick Reference Guide

An abbreviated version of the more detailed Operator’s Manual. Emphasis on brevity, need-to-know or step-by-step instructions.

Inputs: CAD, product feature list, prototype/pre-prod vehicle, engineering and legal approval

Relevance: End-users often reach for their Quick Reference Guide (QRG) first when they need to solve a problem quickly or on the road. While not typically required by law, the QRG represents an important and much-appreciated courtesy for end-users and provides real business value by creating ease-of-use and end-user satisfaction. And while QRGs are sometimes offered in digital form, printed QRGs offer far greater access and provide greater value.

First Responder’s Guide

Critical safety information and invaluable regulatory compliance.

Inputs: CAD, product feature list, prototype/pre-prod vehicle, engineering and legal approval

Relevance: In the immediate aftermath of an emergency, the First Responder’s Guide is designed to ensure the safety of the rescue teams arriving at the scene. EV batteries in particular raise a number of post-accident safety concerns both for rescue crews and vehicle occupants. As one example, it may tell fire fighters how to shut down an EV’s high voltage system, information that could prevent severe or even fatal injuries. First Responder Guides feature critical information on vehicle handling to protect everyone involved and are an invaluable facet of regulatory compliance.

Service and Warranty Manual

Tells the owner which warranties cover a product, along with the limits, parameters and duration of those coverages. It also identifies product service requirements.

Inputs: CAD, product feature list, prototype/pre-prod vehicle, engineering and legal approval

Relevance: This documentation is required by federal law.

Your EV start-up may be new, but automotive product support has been legally mandated for well over 50 years.

Not an Option: Employ Best Practices

Your company may be new, but automotive product support has been legally mandated for well over 50 years. In that time, we’ve developed methods to help companies:

- Streamline information processes, easing burden-of-effort for the company at large

- Eliminate duplicated effort, reducing wasted resource hours

- Protect information integrity (i.e., ensuring information is accurate and up to date)

It’s nothing esoteric, but strictly speaking there’s a right way and a wrong way to build out an information strategy.

Start-ups have nothing in place yet—as we’ve discussed—which creates a huge burden of work, and that’s the bad news, right?

The good news is start-ups have nothing in place yet, so there’s nothing to fix, there’s nothing to rebuild, there’s nothing to overwrite. There’s no “baggage”.

New companies have an incredible advantage: it’s possible for them to create their strategy correctly from the ground up.

These companies would do well to apply all the lessons others have learned the hard way.

By doing so, they can guarantee the success & profitability of their EV Aftersales operations.

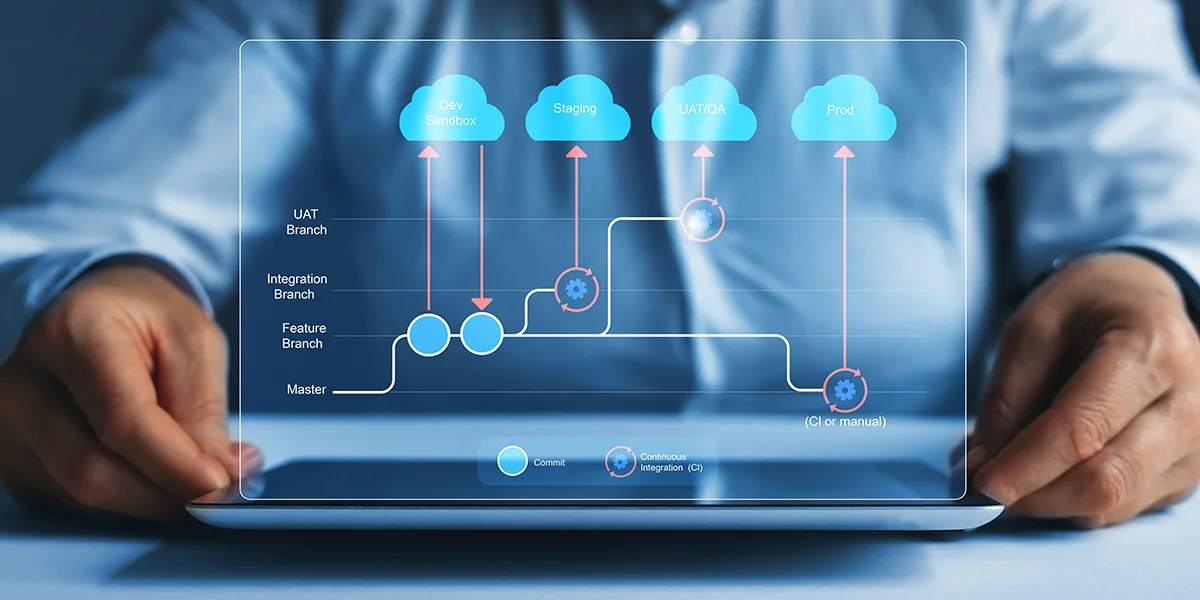

Put an End to Silo Syndrome

BEV brands face the same central issue that’s plagued automotive technology for decades—Silo Syndrome.

It’s natural for information to end up scattered, especially when developing a new product. Unless an organization develops measures to actively prevent it, different aspects of info for a single product will invariably be owned and maintained by different teams and at different levels within the same company.

Such a structure leads to duplicated effort, which wastes resource hours.

But far worse is inadvertent duplication of the same information. It quickly becomes difficult to determine what information is outdated, what information is updated, or where to look for definitive versions. This creates confusion and more wasted time for those who own and maintain the information, but it creates an absolute nightmare for the technicians who rely on that information to do their jobs.

Result: your whole service operation suffers.

Service becomes costly and time-consuming when it should be a source of profit.

Aftersales Should Be More Than an Afterthought

Building a good aftersales operation demands careful forethought and proactive big-picture attention. Good aftersales only happens when companies make it easy on themselves, proactively employing smart, cutting-edge best practices from Day One.

Companies who’d like to maximize the success & profitability of their EV Aftersales operation should carefully consider the above checklists, decide which points are relevant to their specific product suite, and be sure to cover each of those bases in a comprehensive way.

Those who are serious about attaining the customer trust and long-range savings that come with a highly efficient information program should seek out dedicated information suppliers. Or, better yet, expert suppliers with proven expertise and end-to-end provider capability.

Speaking from experience, that care will pay dividends.

DOWNLOAD THE INFORMATION STRATEGY CHECKLIST

I realize we’ve presented a good deal of information here and, of course, the whole point is to simplify this process and make it more understandable. To that end, feel free to download the condensed checklist “cheat sheet” below.

Nick Horan

As a former technician turned technical consultant, Nick Horan’s focus is on improving the lives of technicians. For over a decade, Nick has worked in the technical information space, both for customers and in aiding the development of Guided Diagnostics, a platform designed to make complex root cause diagnosis faster, easier and more accurate.