Sound the Alarm: A Growing Shortage of Automotive Technicians

For years the technician crisis was just one doomsayer prediction out of thousands. It’s rapidly become a clear and present reality: we’re losing our automotive technicians. Maybe even more to the point, we’ve lost them.

One TechForce Foundation study suggests by 2024 the industry will find itself short 642,000 automotive, diesel and collision technicians.

How did we get here? What does the ‘technician crisis’ mean? And how can smart companies compensate for a grievous lack of repair and diagnostic resources?

What Caused the Technician Crisis?

The automotive technician shortage didn’t just happen—it represents seismic shifts in culture, education and technology. Plenty of ink has been spilled over our cultural attitude regarding the technical trades. The work simply isn’t valued. Middle-class parents aggressively push their children toward university education and professional careers which, it turns out, are increasingly unavailable to new college graduates.

So, as mass numbers of veteran technicians retire, repair centers find no new technicians to take their place. The automotive technician shortage removes decades of tribal knowledge from the shop floor. This loss cannot be overstated, given the role mentorship and word-of-mouth plays in day-to-day repair work.

For sure, none of this is great news. But it gets worse. Consider current trends in product development—specifically, the fact products are becoming more and more complex at an exponential rate. Electrical operation—once relegated to a few isolated systems—is now integral to every vehicle function. And those functions are rapidly becoming more and more integrated with complex technical systems. Automotive technicians were never the crude luddites of stereotype, but now, as one technician put it, “You have to be an IT specialist as much as a mechanic, maybe more so.”

The end result isn’t simply service shops with fewer techs and no seasoned veterans. It’s shops where, increasingly, no one knows what they’re doing.

What’s a rookie technician to do? Without a veteran to consult, the options are trial and error or static diagnostic procedures.

Symptoms, Causes and Tests

Lengthy diagnostic procedures have been a mainstay of the repair environment from time immemorial. This writer still remembers the Chilton repair books strewn about the house in the early 1980s. But no veteran technician worth their salt relied solely on those books. Rather, they drew from experience, from having seen the same symptoms countless times, from knowing which tests to run on which symptoms, and eventually determining likely root causes through repetitive task execution.

And, remember, those machines were void of any digital components whatsoever.

Without more experienced cohorts to speak with, newbie technicians might rely on step-by-step procedures. They may also start replacing parts, trying different things, hoping that something—anything—might solve the problem. Neither approach is time efficient.

Worse yet, as Mike Reynolds, owner and operator of South Carolina’s Mobile Automotive Service Solutions, explained in a 2020 Knowledge Base webinar, many engineering groups write their automotive service procedures, not to help technicians resolve issues, but to deflect responsibility for failures in their owned vehicle systems.

The High(er) Cost of Fewer Technicians

What that means, first of all, is longer wait times. Try this experiment. Pick up your phone and call your dealership or preferred aftermarket repair shop. Ask them how soon they can look at and repair your vehicle. Can they do it today? How about later this week? Chances are, you’ll wait a week or more before anyone services your vehicle. Good thing your vehicle isn’t broken, because that would be a long time to wait.

And, of course, that’s only half the story. Labor time costs continue to skyrocket as well, driven by—you guessed it—the automotive technician shortage.

This means disgruntled, impatient customers and, perhaps, less-satisfied customers more likely to switch brands at their next purchase. (Does this matter? Well, according to Forbes, “Customers switching companies due to poor service costs U.S. companies a total of $1.6 trillion.” So, one reckons, yeah, kind of.) Conversely, repeat business can boost the profitability of a service operation.

But the real core concern here should be repair bay throughput. The more vehicles you repair in one day, the more customers you can charge in a day. As long as technicians can perform those repairs quickly and accurately—the more revenue you can log and keep. And it becomes difficult to maintain a high throughput when dealing with an automotive technician shortage.

Or does it?

How AI Could Compensate for the Automotive Technician Crisis

If there’s any silver lining to the technician shortage, it’s that it arrives precisely at the same time as AI. And AI is the one technology capable of balancing this resource gap.

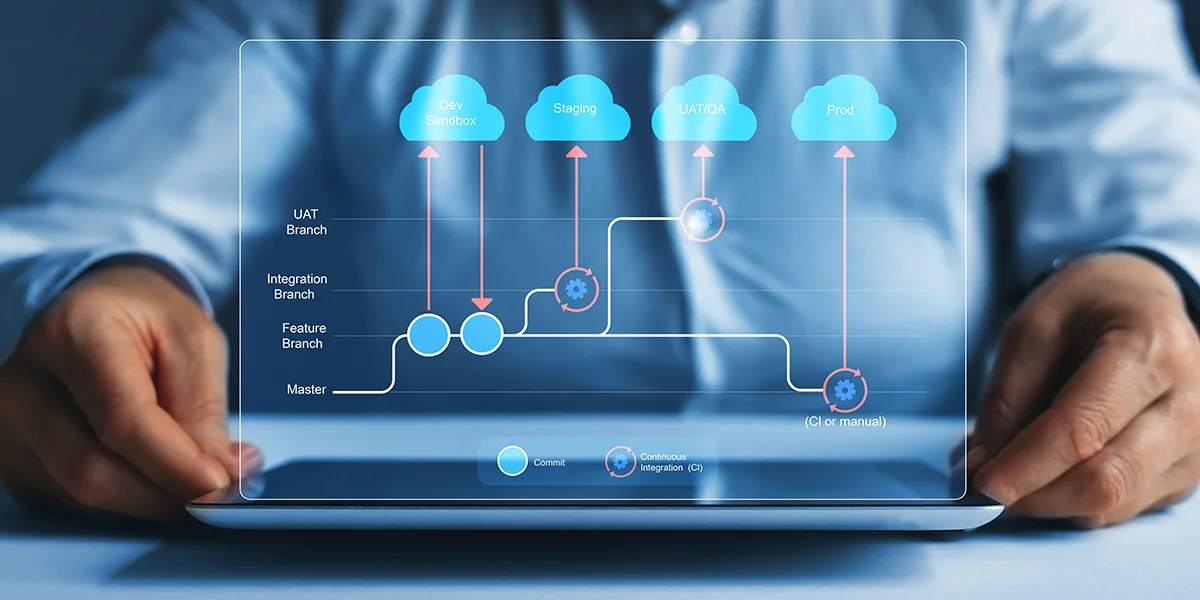

Engineers are finally developing AI diagnostic and repair tools to dramatically level the playing field. They could, feasibly, close the distance between rookie technicians and their highly seasoned counterparts. Tweddle Group’s electrical diagnostic tool, TRACER™, eliminates the need for lengthy trial and error. TRACER analyzes complex clusters of diagnostic trouble codes (DTCs) to identify the most likely root-cause failure, and can even pinpoint that root failure down to the specific pin.

Tweddle Group also frees technicians up from lengthy diagnostic trees with Guided Diagnostics, an integrated diagnostic explorer. Instead of leading technicians through long, step-by-step diagnostic procedures—which cannot, due to their written-down nature, account for any context dynamics whatsoever—Guided Diagnostics approaches repair in a far more logical and modular way, dealing simply in problems, causes, tests and test inputs.

Of course, solutions like these can’t entirely resolve the automotive technician shortage. They can, however, empower manufacturer service operations and aftermarket repair centers to maintain bay throughput despite having fewer techs on the floor. One hopes cultural attitudes will shift once again to recognize automotive repair as a crucial, secure and potentially lucrative profession. In the meantime, service operations should consider AI tools designed to turn newbies into seasoned veterans, and veteran techs into even faster, more accurate versions of themselves.