What IS ADAS Calibration?

ADAS calibration has become a common and necessary service, as most new vehicles now come equipped with Advanced Driver Assistance Systems (ADAS). In fact, 93% of new US vehicles shipped with at least one ADAS feature in 2018. These systems include automatic emergency braking, adaptive cruise control and blind spot monitoring. Each aims to help end users maintain safe driving habits. ADAS features will continue to increase in the coming years. The Highway Loss Data Institute estimates 71% of registered vehicles will have rear cameras and 60% will have rear parking sensors by 2026.

According to a National Highway Traffic Safety Administration survey, driver error plays a role in 94% of all crashes. According to NHTSA, that number decreases with the presence of ADAS features. The Highway Loss Data Institute and Insurance Institute compared crash rates and insurance claims for vehicles with and without ADAS equipment. They found forward collision warning with autobrake decreased front-to-rear crashes by 50%. Rear automatic braking decreased backup crashes by 78%. Crash severity also decreased, lowering the probability of serious injuries and death. By this math, ADAS technologies could potentially prevent over 20,800 deaths per year—62% of total traffic deaths.

However, as with any complex technology, ADAS creates its own unique concerns, mostly around matters of vehicle operation. It also brings great opportunity.

Calibration is Key

ADAS features rely on finely-tuned cameras and sensors. If something disrupts any of these components, even by a single degree, they can render whole systems ineffective or even dangerous. For drivers who have learned to rely on these systems, this is a major safety concern. This is why careful component testing and recalibration must occur after the slightest fender bender or standard, everyday procedures like wheel alignment and windshield replacement.

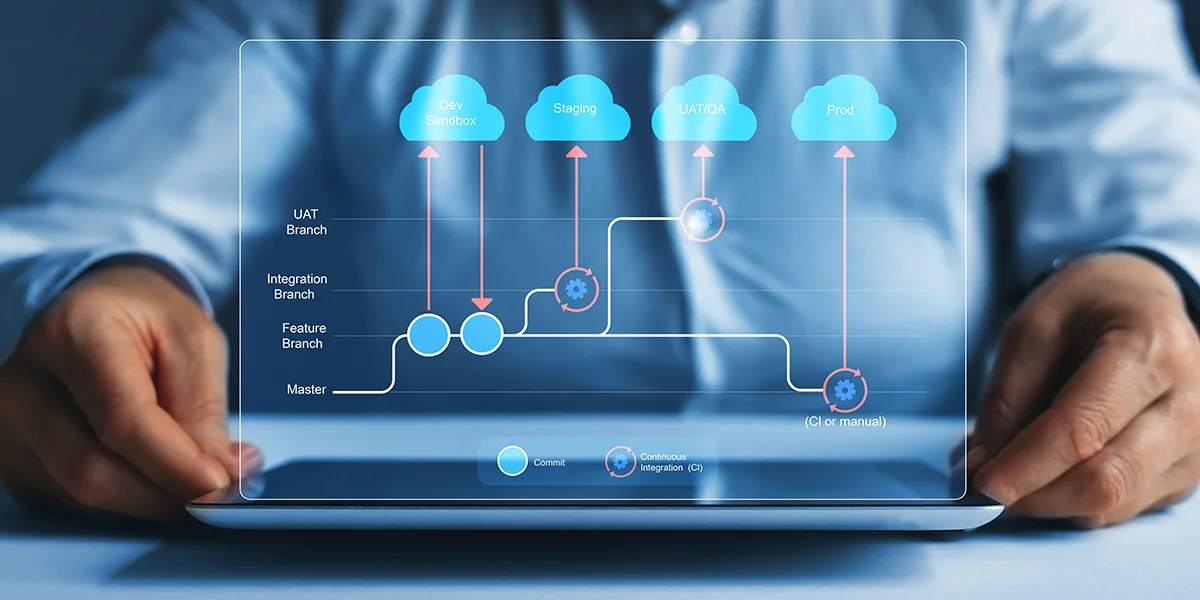

Static vs. Dynamic ADAS Calibration

There are two types of ADAS calibration.

In-shop, or static calibration, involves performing manual measurements and special aiming targets to aid camera and sensor alignment. After this process, many vehicles require dynamic or “on-road” calibration. This is the preferred method for camera sensors, and the only one performed.

Radar sensors require a static adjustment followed by dynamic calibration. Dynamic calibrations require a factory scan tool followed by driving the car according to specified requirements.

Due to system complexity, even simple repairs become more time-consuming—and expensive—for ADAS-equipped vehicles. Calibration requirements differ by vehicle and manufacturer. Technicians need proper training and equipment to perform a proper repair.

Streamlining the ADAS Calibration Process

Only trained professionals should perform ADAS calibrations. ADAS calibrations require a number of advanced (see: expensive) tools. That’s why most repair shops send vehicles to the dealer for this service. This means more time, more labor and more money. Yet the law may still hold a repair shops liable for improper calibration if they outsource this work.

Shops can avoid these risks by bringing ADAS calibrations in-house.

According to collision repair specialist Mike Anderson, bringing calibration repairs in-house can reduce cycle time by up to two days. It can also reduce or eliminate the need for rental cars and improve overall customer satisfaction. Best of all, ADAS calibration expenses are often reimbursed. In the Collision Advice and Crash Network’s Who Pays for What? survey, 87% of shops said they’re usually reimbursed for ADAS calibration charges. Depending on the type of calibration performed, that could range from $250 to over $600.

Learning Curve

In-house ADAS calibration work supplements cash flow but involves a major learning curve. OEM-specified targets and other equipment is required. Other requirements include level floors, nonreflective paint and a clean, open workspace free of sunlight and shadows. Even technicians’ clothing must meet certain standards to ensure effective calibration. Again, one degree of misalignment is all it takes to cause major ADAS system failure. According to one specialist, “Properly calibrating ADAS systems is a matter not of inches but of millimeters.”

Automotive professional David Kraus describes performing a minor repair on a vehicle and then recommending ADAS calibration to follow. The shop owner disagreed, since the system itself had suffered no direct damage. The customer picked up their vehicle, left the shop, and soon entered an intersection to turn left. The misaligned radar unit detected something in front of the vehicle. Forward collision warning system forced the vehicle to stop—in the middle of the intersection. Oncoming traffic struck the vehicle on both sides.

Aftermarket Systems

Awareness of the revenue-generating potential of ADAS calibrations has led to some safety concerns. Specifically, the recent arrival of portable calibration services, performed via a collapsible device. This device is available for anyone to purchase as low as $7,000. It fits in the back of a truck and can then perform calibrations in any location. This is a dangerous concept, given the strict guidelines for proper calibration.

It’s to buy a mobile calibration unit but the risks may be too great. Collision shops receive an increasing number of requests to re-do ADAS calibrations previously performed incorrectly by these mobile operators.

Conclusion

When it comes to ADAS features, shortcuts and cut corners can lead to huge issues. If a collision shop meets OEM specifications, they should reconsider outsourcing ADAS calibrations. Repair shops—and customers—will benefit greatly from properly regulated in-house calibration services.