The Age of the Electronic Parts Catalog

The Electronic Parts Catalog has created a new era in ordering replacement parts.

Parts ordering was, for decades, a process based in paper. Technicians and engineers flipped through large printed manuals and catalogs to identify the parts they needed. Then they picked up the phone, and engaged in endless phone calls.

“Before we ever had the online catalogs,” says Nicole Glenn, Service and Parts Director at Freeway Honda in Birmingham Alabama, “if there was an updated part number, we wouldn’t find out for 24–48 hours, at least. And then you had to go back and call the part vendor. Because the vendor, back when we used a paper catalog, could take 5–7 days to even let you know.”

This dated process put massive strain on efficiency. It also threatened the accuracy of the parts orders themselves.

Then came the electronic parts catalog or EPC, a virtual database of all parts for maintenance and repair. EPCs allow dealerships and repair shops to perform fast lookups of the parts required for the issue at hand. EPCs eliminate middlemen, cut financial waste and increase customer satisfaction.

How Does an Electronic Parts Catalog Work?

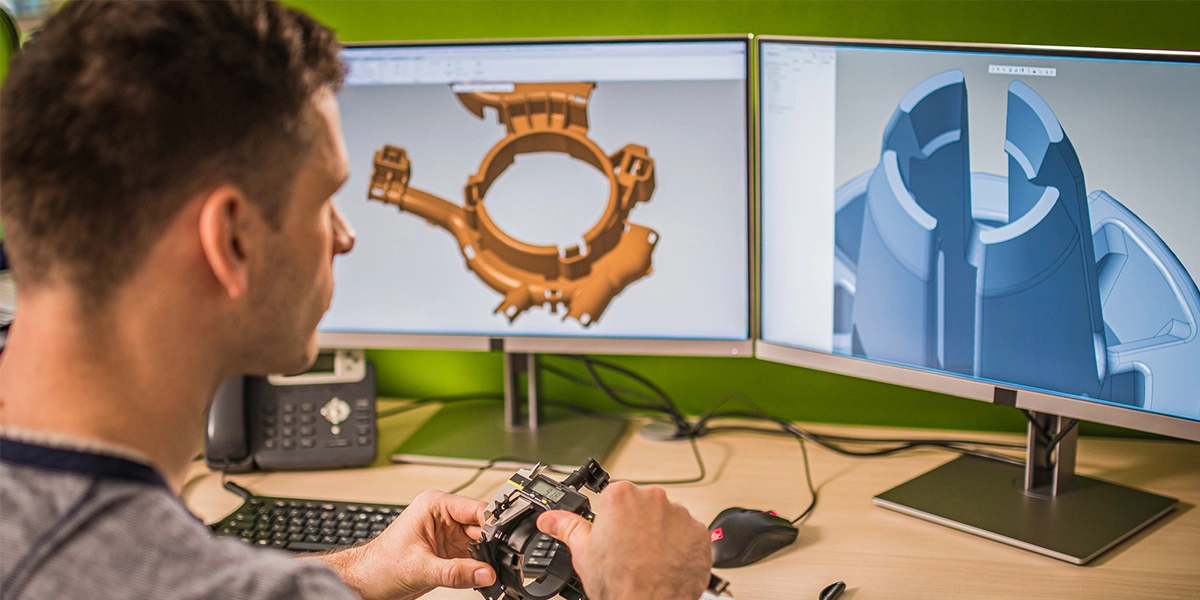

Today’s EPCs are more than just digitized versions of their paper counterparts. They contain a wide range of valuable product information, from data sheets and engineering drawings to 3D CAD models and other imaging options.

Here are four ways an electronic parts catalog can radically improve your maintenance or repair business:

1. AN EFFECTIVE Electronic Parts Catalog ProvideS Immediate Updates and Increased Accuracy

One of the greatest advantages of an EPC is automatic part information updates.

“A technical publishers can make changes and the electronic parts catalog updates automatically, in real time,” says Glenn. “And you can look up the part right then and there. You don’t have to pick up a phone. You don’t have to call and see if another local dealership has [the part you need].”

These real-time updates reduce human error and improve FTFRs (First Time Fix Rates).

2. Improve Customer Satisfaction

By reducing error rates and customer wait times, a good EPC can improve customer satisfaction and return business. This is critical in an industry where customer acquisition is more expensive—and challenging—than customer retention. Research suggests many customers abandon a company after just one negative experience. This leaves very little room for the type of error created by manual parts ordering.

Electronic parts catalogs help service centers and manufacturers take control of the situation and ensure a positive customer experience.

3. Reduce Turnover and Training Efforts

Turnover and training are some of the biggest drains on time, effort and money in any organization. A well-designed electronic parts catalogs requires no intensive training effort. There’s no need to hire new talent—current employees can adapt to an EPC quickly. Visual identification makes the ordering process even easier.

4. Cut Financial Waste

All the above benefits function in tandem to produce significant cost-saves. Lower rates of error mean fewer corrective actions. Higher customer satisfaction creates greater customer retention, and reduced turnover translates into less expensive resource onboarding. Taken together, these saves offer significant benefits for an organization.

Take Action

Companies who haven’t already transitioned to the electronic parts catalog format should seriously consider the move. Those who have should take stock of their existing software:

- Is it the most efficient option?

- Does it suit the unique needs of your operation?

- Does it link directly to a product’s original bill of materials? Does it offer instant updates when the related components change?

- Does it offer exploded 3D and 2D parts views for easy part identification?

There are plenty of options out there. Proper research will help ensure a company stays one step ahead.